Hot-selling Carousel Line Concrete Component Mould Tilting Machine - concrete distributor – Xindadi

Hot-selling Carousel Line Concrete Component Mould Tilting Machine - concrete distributor – Xindadi Detail:

Equipment Function

The function of concrete distributor is to distribute the concrete for the pallet for the PC components. The distribute operation adopts automatic intelligent control, and the distribution procress can be automatically evenly distributed for each pallet according to the pre-entered program.

Equipment Features

n X, Y direction walking mechanism can ensure that the distribution mechanism covers the pallet table in all directions。

n The lifting function of the concrete distributor can meet the requirements of different thickness components.

n The gate mechanism can be flexibly open and close and carry out single-door or multi-door distribution procress, which greatly meets the needs of multi-shape layout of the pallet table.

n The mixing shaft of the concrete distributor has the function of uniform material, and can also prevent the material from coagulating and segregating when stored in the hopper for a long time.

n The forced discharge method of the concrete distributor can adapt to the discharge of small slump materials.

n The hydraulic system can quickly open and close the hopper gate to ensure accurate distribution.

n When the equipment is suddenly powered off, the hydraulic system can open the hopper, remove the materials in the hopper, and protect the equipment.

n The metering system can display the material storage in the hopper at any time.

n The digital control system is equipped with a USB interface, which can directly read related information from the central control system.

Composation of the equipment

Standard item :

n Steel structure bracket

n X direction walking mechanism

n Y direction walking mechanism

n Distribution mechanism

n Safety guard

n Lifting system

n Metering system

n Hydraulic system

n Digital control system

Optional item:

o Wear-resistant liner

o Cleaning device

o Cross-line selection

o Automated programming system

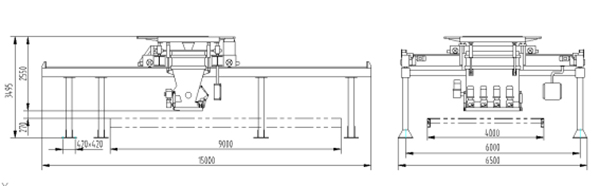

Main technical parameters

Rated volume of hopper: 2.5m³

X direction speed: 0~30m/min

X direction running motor rated power: 2×1.5kW

Walking speed in Y direction: 0~30m/min

Y direction running motor rated power: 1.5kW

Stirring shaft speed: 0~20r/min

Stirring shaft rated power: 4 kW

Distribution shaft speed: 0~40r/min

Distribution shaft rated power: 4×3.0kW

Distribution gate quantiry: 10

Hydraulic working pressure: 16MPa

Hydraulic rated power: 4 kW

Equipment weight: ≈23000kg

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Hot-selling Carousel Line Concrete Component Mould Tilting Machine - concrete distributor – Xindadi , The product will supply to all over the world, such as: Sudan, Jakarta, Gambia, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.