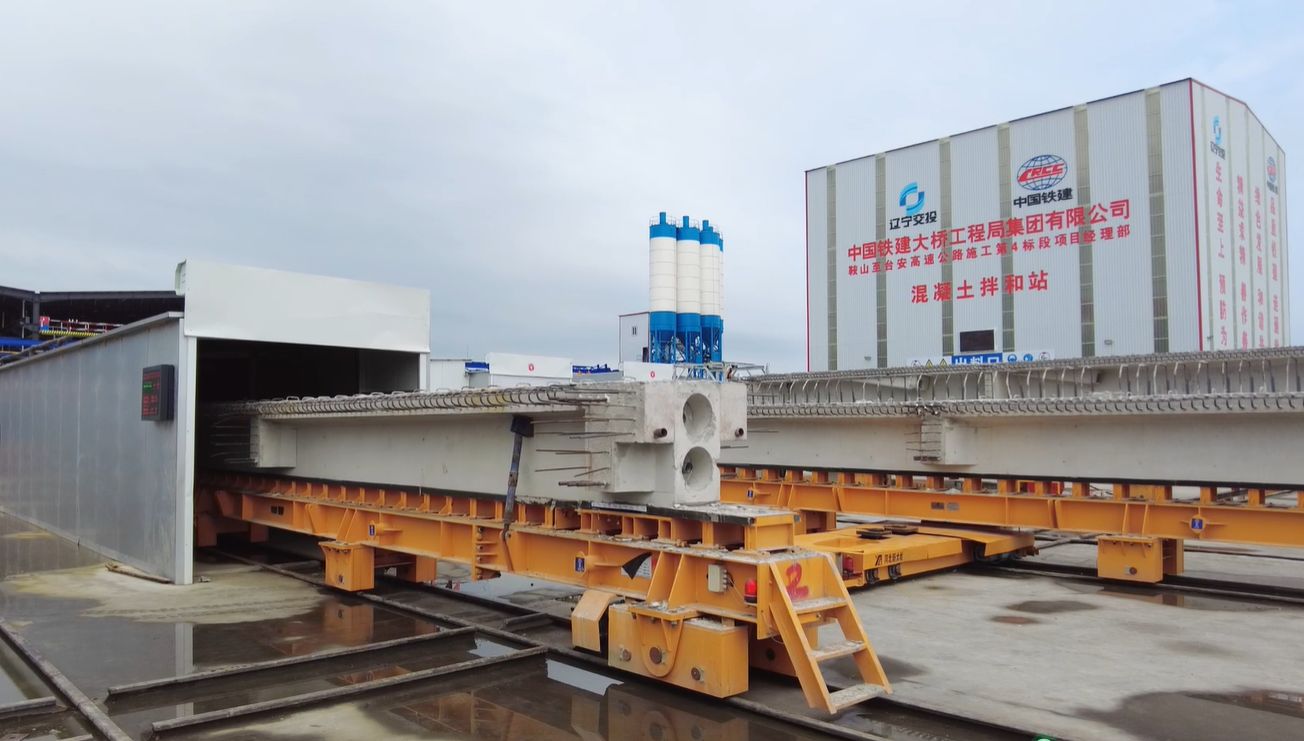

The intelligent beam factory designed and produced by Hebei Xindadi for Antai Expressway has passed the preliminary trial production and officially went into production. This is the first intelligent beam factory in Liaoning Province.

The intelligent beam factory adopts a mobile pedestal production line type and is divided into 8 functional areas: steel bar processing area, mold binding area, shifting area, CNC distribution area, intelligent curing area (automatic spraying area and winter curing area), intelligent tensioning and grouting area, beam storage area, and beam yard information center.

Intelligent Beam Factory—— T beam production line

1. Adopting intelligent hydraulic mold

Automatically coordinate the actions of various parts and demold as a whole.

2. The first diagonal beams prefabrication system in China

Traditional production lines are unable to prefabricate, and the diagonal beam prefabrication system creatively adds a diagonal mold demoulding device, which solves the problem of automatic demoulding of diagonal beams and realizes the intelligent assembly line prefabrication of diagonal beams.

3. Intelligent distribution system

The automatic docking of the concrete distributor and the bucket is realized, and the concrete transportation is automatically operated.

4. Intelligent curing system

The curing chamber is built to the standard of an experimental constant temperature curing room. After the beam enters the curing chamber, it is started with one button and the temperature and humidity are automatically adjusted. The system automatically fits the concrete strength curve, which is highly efficient and energy-saving.

With the official put into production of the intelligent beam factory, the construction of the Anshan-Tai’an Expressway will progress rapidly. In the future, our company will continue to uphold the development concept of innovation, greenness and efficiency, and provide new quality productivity for the high-quality development of the industry.

Post time: Sep-04-2024