Recently, the two “New Jersey Barrier Intelligent Production Lines” independently developed, designed, and manufactured by Hebei New Land Electromechanical Manufacturing Co., Ltd. have been put into operation in the precast intelligent factories of the T8 and T9 sections of the Changshen Expressway Hehui Section Expansion Project. This is another intelligent precast production line created by our company using digital technology, realizing the intelligent production and lean production management of New Jersey barriers.

The New Jersey (concrete) barrier is a wall-type barrier with a convex cross-section used to separate highway lanes and reduce damage in the event of a collision between vehicles and the barrier. The intelligent production line for New Jersey barriers can achieve fully automatic opening and closing of molds, CNC cleaning of molds, fully automatic spraying of mold release agents, intelligent transportation of reinforcing bars, automatic placement of reinforcing bars, CNC batching of concrete, intelligent curing, automatic lifting and flipping of components, and automatic coding of components, achieving intelligent and labor-saving production of New Jersey barriers, greatly improving production efficiency, and realizing green and cost-effective goals.

Fully automatic opening and closing of molds:

Using a highly precise positioning system, it automatically aligns the mold opening and closing buckles, achieving automatic opening and closing of side molds and double-sided end molds, with the entire process under automatic control.

CNC cleaning of molds:

Fully automatic cleaning and dust removal, with specially designed cleaning components that maintain good contact with the interior of the mold cavity, protecting the mold and maximizing the cleanliness of the mold cavity surface.

Fully automatic spraying of mold release agents:

Using imitation spraying components, the mold release agent is sprayed automatically with dual-action spraying and wiping, avoiding the accumulation and dripping of mold release agents on the surface of the mold cavity.

Intelligent transportation of reinforcing bars using RGV

RGV adopts laser automatic navigation, intelligent avoidance sensing, and other technologies to achieve intelligent transportation of finished steel bars, connecting the steel bar storage area with the steel bar casting area.

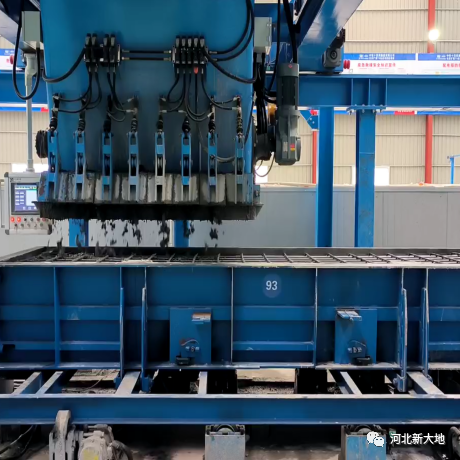

Automatic steel bar casting:

It can intelligently recognize the position of steel bar cages and automatically grab and place them with fully-braked lifting tools, ensuring high installation accuracy.

Concrete CNC batching:

It adopts a patented technology of spiral batching, allowing individual batching and replenishing at each discharge port, ensuring high batching accuracy and effective control of concrete consumption.

Automatic lifting and flipping of components:

Vacuum suction cups automatically grab components without damaging the surface, completing the flipping operation automatically, achieving the vertical placement of New Jersey barriers.

For many years, Hebei Xindadi has served in the fields of construction engineering, municipal engineering, road and bridge engineering, rail transit, and new energy construction, relying on advanced technology and excellent products. The company has successfully implemented more than 980 high-quality concrete prefabrication equipment production lines, establishing a good brand reputation based on outstanding quality and service.

Hebei Xindadi has developed into a large comprehensive base integrating overall planning and design, equipment manufacturing, mold design and production, and extended technical services. Through leading hardware and software strength, excellent service awareness, and efficient operation management, Hebei Xindadi comprehensively promotes industrial development and industry upgrading, aiming to become a world-leading enterprise in precast concrete processing and equipment.

Post time: Dec-10-2022