On September 22, amid the sound of firecrackers, Jiangsu Tongtai Green Building Materials Technology Co., Ltd. witnessed the first pouring of a 30-meter small box girder, marking the accelerated advancement of the large-scale production of the smart girder field for this project.

Jiangsu Tongtai Green Building Materials Technology Co., Ltd. has taken on the prefabrication task for all box girders of the New Yangtze River Expressway Bridge. Hebei Xindadi provides comprehensive solutions for the construction of the “smart girder field,” including process planning, equipment design, production manufacturing, installation and commissioning, intelligent upgrading, and production training.

The box girder molds adopt a modular design with replaceable sections for precast partition production.

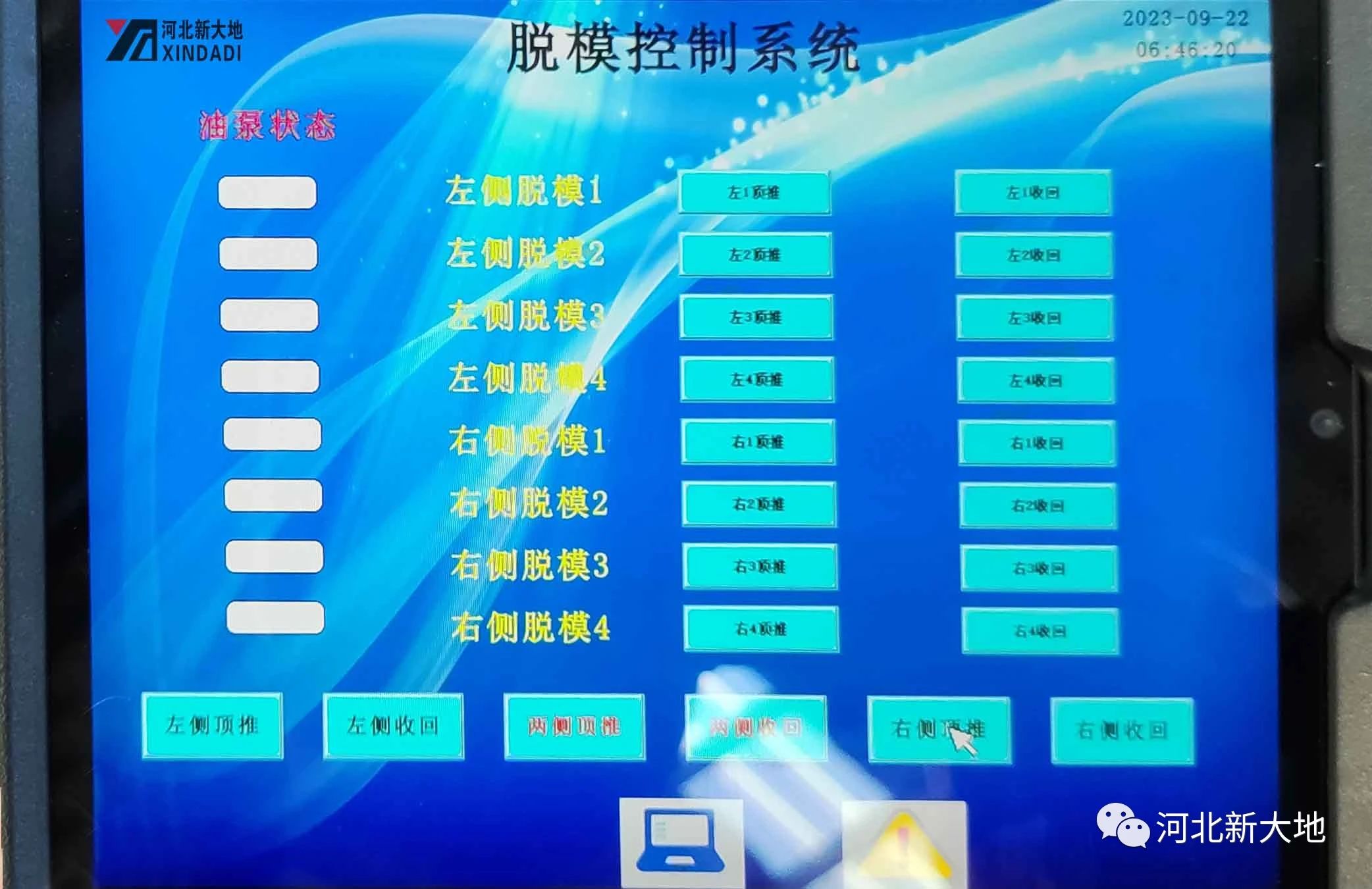

The hydraulic cylinders are controlled by a digital visual control program, with the stroke data of multiple cylinders compared and synchronized for CNC-controlled smooth and synchronous mold opening and closing. This allows for quick installation of the mold and efficient production of the box girders, ensuring prompt delivery and use of the products.

The molds are made of polished stainless steel, resulting in smooth and shiny product components. The attached vibration system uses an automatic multi-stage frequency conversion system, allowing for the selection of vibration areas. The overall operation is controlled through a fixed control panel and a tablet computer, making the operation convenient and efficient.

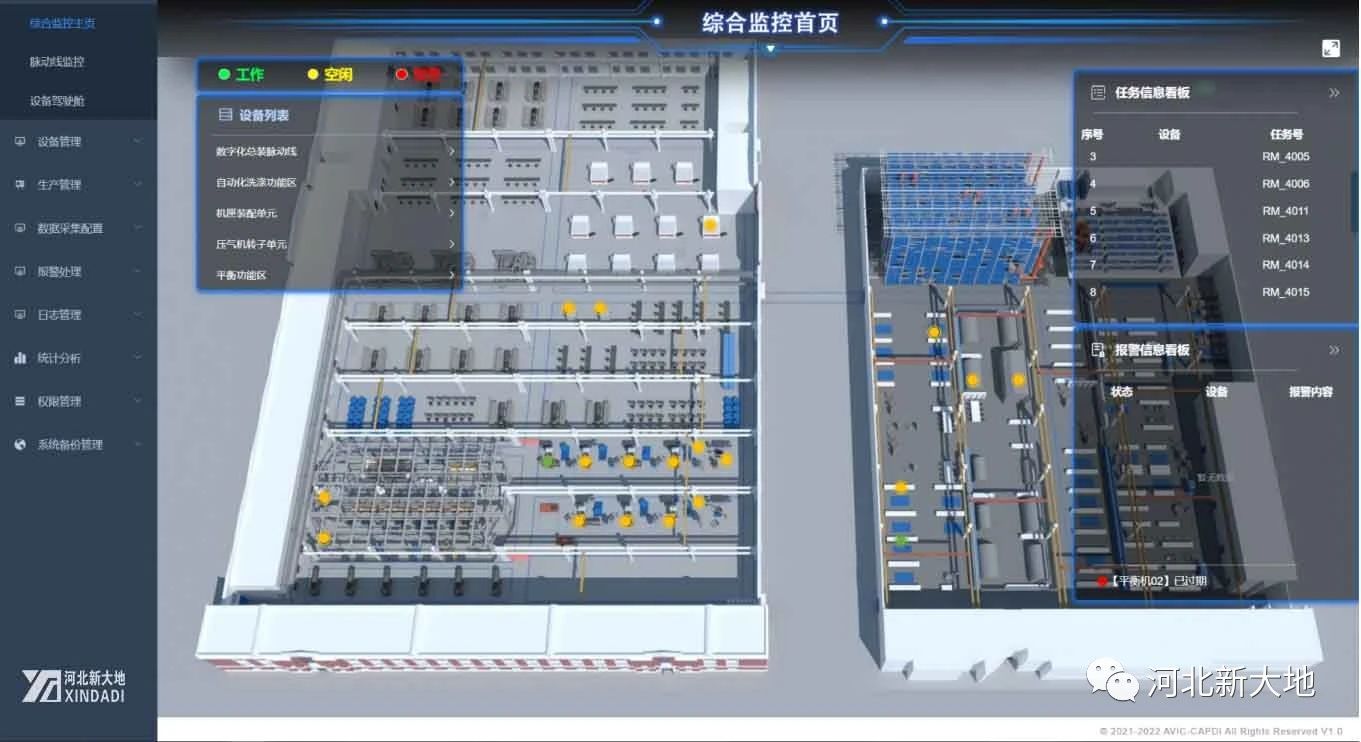

Additionally, Xindadi has provided a SCADA system for this project, which is linked to hydraulic templates, mobile pedestals, steam curing systems, and other equipment to collect data from key equipment and achieve real-time data sharing between software and hardware. The system monitors the main process stations, providing real-time alerts for abnormal information, ensuring transparency in the production process and improving production efficiency.

Post time: Oct-23-2023