OEM Factory for Beam Mould - Curing chamber – Xindadi

OEM Factory for Beam Mould - Curing chamber – Xindadi Detail:

Equipment function

The curing chamber system are suitable for the curing of prefabricated components after pre-curing and smoothing; the automatic control is used to maintain a certain temperature and humidity in the chamber. The pre-cast components through static stop, heating, heat preservation, cooling Process becomes a prefabricated component of the finished product Equipment feature

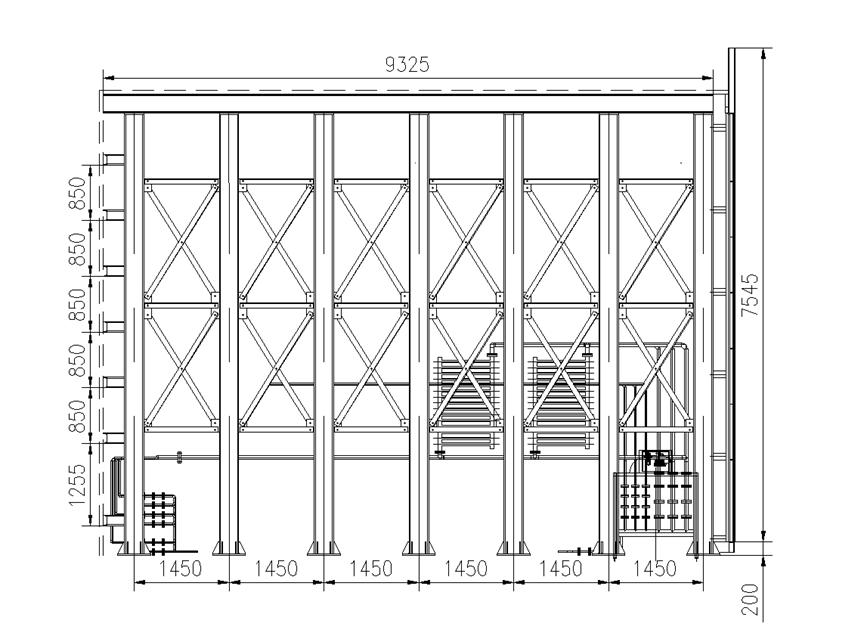

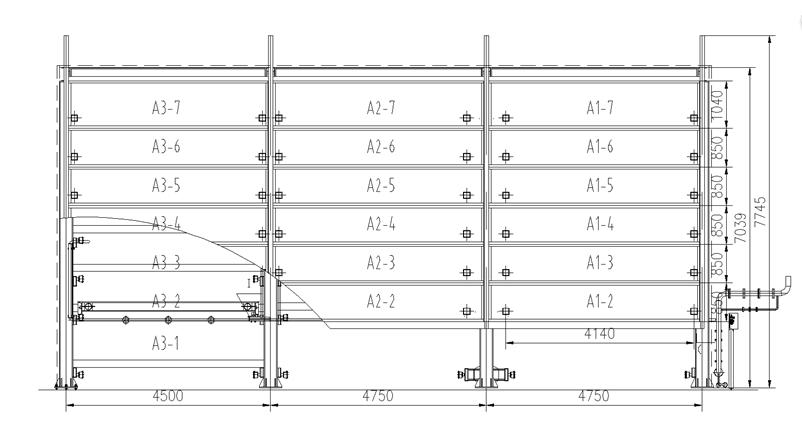

n The equipment is a three-dimensional layered model, making full use of the height space of the production site

n The temperature and humidity in the chamber are automatically controlled, and the temperature, humidity and time can be controlled and adjusted

n Each row of chamber uses a set of control system separately, separate control to improve production efficiency

n Install an automatic drainage system to achieve water drainage

Equipment composation

n Steel structure

n Curing chamber door

n Piping system

n Insulation system

n Electrical system

n Hydraulic system

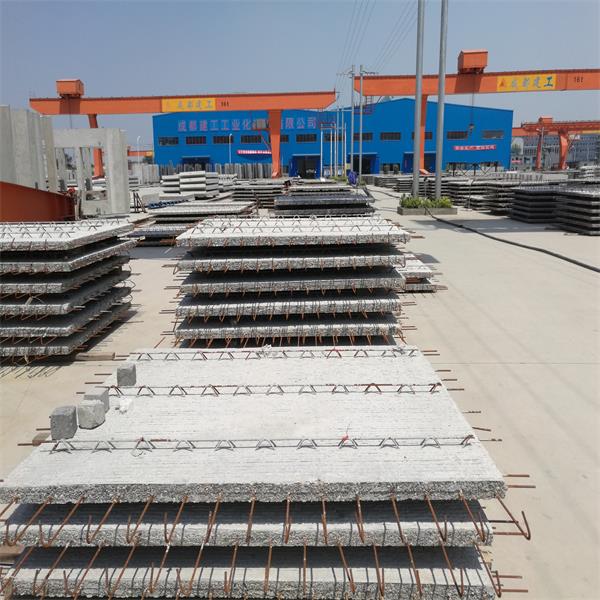

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for OEM Factory for Beam Mould - Curing chamber – Xindadi , The product will supply to all over the world, such as: Spain, Honduras, Surabaya, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.