Personlized Products Carousel Line Concrete Component Pallet Flatting Machine With Vibrating - stacker – Xindadi

Personlized Products Carousel Line Concrete Component Pallet Flatting Machine With Vibrating - stacker – Xindadi Detail:

The stacker sends the polished or roughened PC components and their pallet from the roller conveyor line to the designated location of the curing chamber;and the cured PC components and their pallet are taken out of the curing pallet and transported to the roller conveyor line

The stacker control system has two control modes, manual and automatic. The automatic mode can set the action cycle arbitrarily, and the site can be unattended.

Equipment composation

Standard item:

n walking system

n frame

n lifting system

n Pallet conveyor system

n Jack/pull pallet mechanism

n Vertical positioning mechanism

n Horizontal positioning mechanism

n Door lift mechanism

n Control System

n Hydraulic system

n controlling software

n Guardrail, cage ladder

Optional item:

o Simulative monitor system

o Video monitor system

o Walking track

Equipment feature

n The lifting system can lift and lower the jacking mould convey system to ensure that the lifting points of the jacking mould convey system are synchronized with each other.

n The stacker has a based on floor running structure, which is conducive to improving the rigidity and stability of the curing chamber.

n The walking system has a guide device and a horizontal positioning device to ensure the accuracy of the vehicle body along the track and the repeated positioning accuracy of the lifting process.

n The jacking system of the mould has vertical fine adjustment and positioning devices to ensure the accuracy of the position of the pallet in the height direction of the curing chamber.

n Program control, automatic signal collection, automatic execution, unattended function can be realized.

n The position and sequence of entering and leaving the curing chamber can be set arbitrarily, and the working cycle can be formed according to the choice.

n The lifting control adopts high-precision absolute value sensor, the position control is accurate, and the accurate position ofpallet is always transmitted.

n The system has the functions of simulation monitoring and video monitoring, which can record the entry and exit time of the pallet of the curing chamber and form a maintenance record chart.

Technical Parameters

Total power of equipment 75kW

Traverse speed 0-22m/min

Traverse power 2×3kW

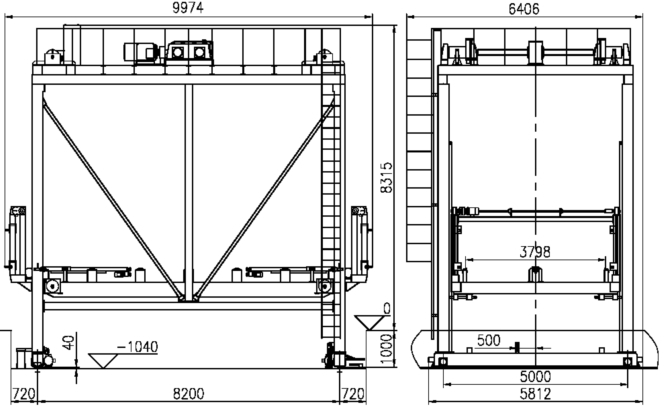

Gauge 8200mm

Lifting power 55kW

Lifting ability 250kN

Lifting height 8000mm

Lifting speed 0-10m/min

Vertical positioning accuracy ≤2mm

Vertical positioning power 0.75kW

Jacking force 6kN

Jacking speed 9m/min

Jacking power 1.5kW

Jacking stroke 1300mm

Horizontal positioning accuracy ≤2mm

Door lifting force 8kN

Door lifting speed 9m/min

Door lifting stroke 1050mm

Door lifting power 1.5kW

Equipment weight about 24000kg

Iinstructions

1. Outstanding drawing (taking 4000×9000 pallet as an example):

n Template 4000×9000×290mm

n Elevation of conveyor line 400mm

Paired curing chamber:

n Passing layer height 1280mm

n Curing layer height 850mm

n Curing layers 6

2. According to different template types, there are suitable:

n 4000×6000×290mm

n 4000×8000×290mm

n 3500×9000×290mm

n 3500×10000×290mm

n 3200×12000×310mm

Other series of stacker are available, and can also be customized according to customer requirements.

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for Personlized Products Carousel Line Concrete Component Pallet Flatting Machine With Vibrating - stacker – Xindadi , The product will supply to all over the world, such as: Monaco, Thailand, Sacramento, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.