Prestressed Concrete Components Production Line

★Introduction to prefabricated prestressed concrete components

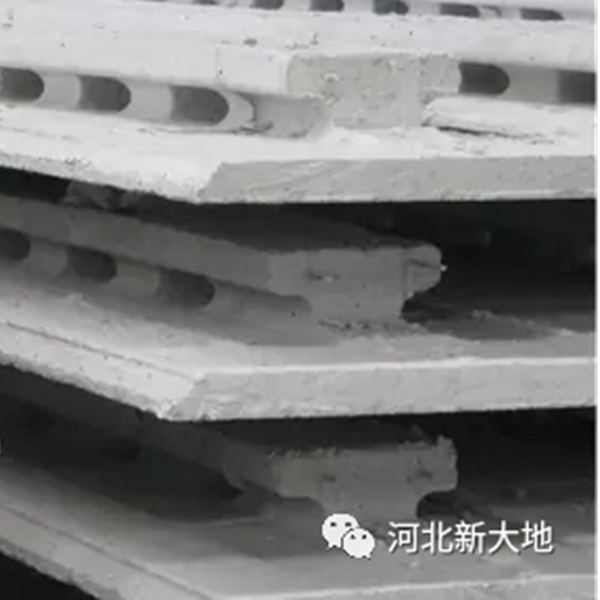

As a mature structural system, prestressed concrete structure has been widely used in a large number of engineering structures, especially with the vigorous development of prefabricated buildings in recent years, in order to adapt to large-span public buildings and the market for cost reduction and efficiency enhancement The application ratio of prefabricated prestressed lattice girder panels, beams, columns and double T-type components in prefabricated buildings is also increasing year by year, which has the advantages of high rigidity, good crack resistance, no increase in steel consumption, and template saving.

★Development of Series Production Line of Prestressed Concrete Components in Hebei Xindadi

1.In 2005 High-speed rail track slab production line (Beijing-Tianjin Intercity)

Hebei Xindadi Electromechanical Manufacturing Co., Ltd. participated in the construction of my country’s first Beijing-Tianjin intercity high-speed rail track slab yard, and developed the first domestic high-speed rail track slab production line equipment.

2.In 2010 Prestressed sleeper circulation production line

Hebei Xindadi Electromechanical Manufacturing Co., Ltd. participated in the construction of my country’s first Beijing-Tianjin intercity high-speed rail track slab yard, and developed the first domestic high-speed rail track slab production line equipment.

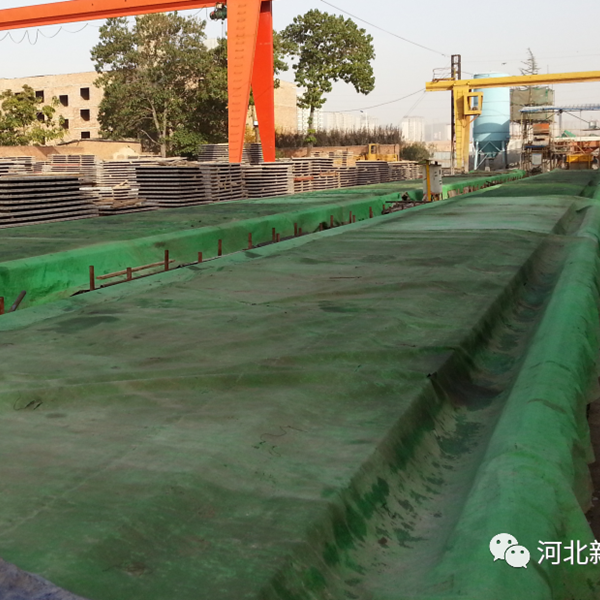

3. In 2012-2014 the first generation of prestressed concrete lattice girder panel long-line table production line

Relying on the mature experience accumulated in the production equipment of prestressed sleepers and track slabs, Hebei Xindadi closely cooperates with the needs of customers, and implements a number of prestressed long-line table production lines in Xi’an, Yangzhou, Taizhou, Jincheng and other places,and realizes the dual control of prestressed tension and the flexible control of the elongation of prestressed steel wire.

4.In 2015-2016 the second-generation prestressed concrete lattice girder panel long-line table production line

On the basis of the first-generation prestressed concrete lattice girder slab long-line table production line, Hebei Xindadi continued to track customer needs and developed the second-generation prestressed concrete lattice girderd slab long-line table production line to meet the national standard prestressed lattice girder slabs and PKⅡ type prestressed lattice girderd slabs and also meet the production and use of non-prestressed components. For the first time, the movable integral tensioning equipment is used in the project.

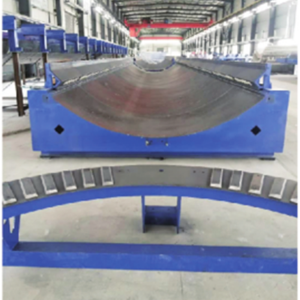

5.In 2017 the first (set) prestressed concrete double-T plate expandable combined long-line table production line in China

Combined with the “13th Five-Year Plan” national key research and development plan, the “Green Building and Building Industrialization” key project “Prestressed Concrete Component Expandable Combined Long-Line Table Production Line” project, Hebei Xindadi participated in and developed the “Prestressed Concrete Component Expandable Combined Long Line Table Production System”. This project breaks through the conventional single-mode production method of double T boards, and realizes the production method of expandable combined long-line table; at the same time, it has the characteristics of self-sustaining, nomadic, and easy disassembly and assembly, and can produce different heights, different widths, and different lengths of prestressed concrete double T slabs.

In the past 5 years, Hebei Xindadi’s prestressed concrete double-T plate expandable combined long-line table production line has been successfully applied in projects in Shenzhen, Haiyan, Wenzhou, Tangshan and other places.

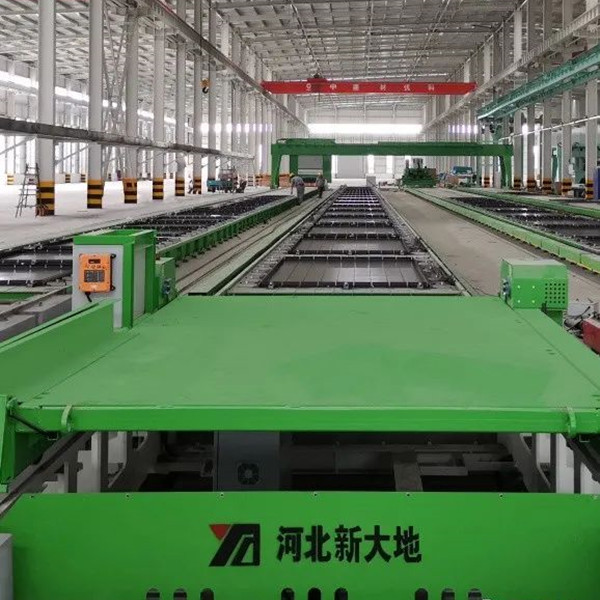

6.2019-2021 the third-generation prestressed concrete lattice girder panel long-line table production line

On the basis of the original mature technology, Hebei Xindadi once again innovated and developed a new generation of automatic prestressed long-line table production line technology, which can meet the needs of each production stage of prestressed products, and integrates automatic cleaning and spraying equipment, automatic film covering and roughening equipment, automatic high-speed hopper, distributing vibrating machine, intelligent tensioning equipment, mobile plate lifting machine, mobile plate conveying machine supporting equipment, automatic maintenance and temperature control system can realize intelligent maintenance operations, and can remotely monitor the running state of equipment operation. It can be used for intelligent production of prestressed concrete lattice girder panels,PKIII type panels and other panel components.