Quality Inspection for Concrete Bed Flatting Machine With Vibrating - Battery Mould – Xindadi

Quality Inspection for Concrete Bed Flatting Machine With Vibrating - Battery Mould – Xindadi Detail:

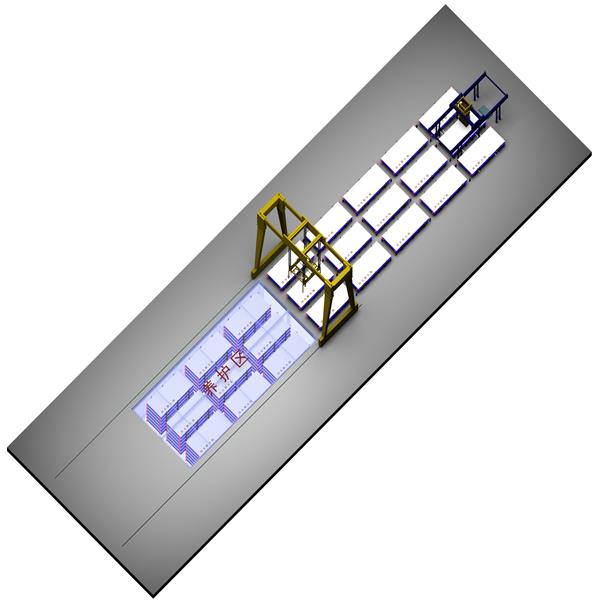

The compact Xindadi battery moulds simplify the production process of vertically fabricated wall and floor slabs with smooth mould surfaces on both sides. Battery moulds can be used as stationary as well as mobile systems.

We have completely revised and optimised the Xindadi battery moulds that have proven themselves over decades of use. Whoever wants to manufacture wall panels and other flat concrete components with smooth mould surfaces on both sides relies on the space-saving design and high productivity of our battery moulds.

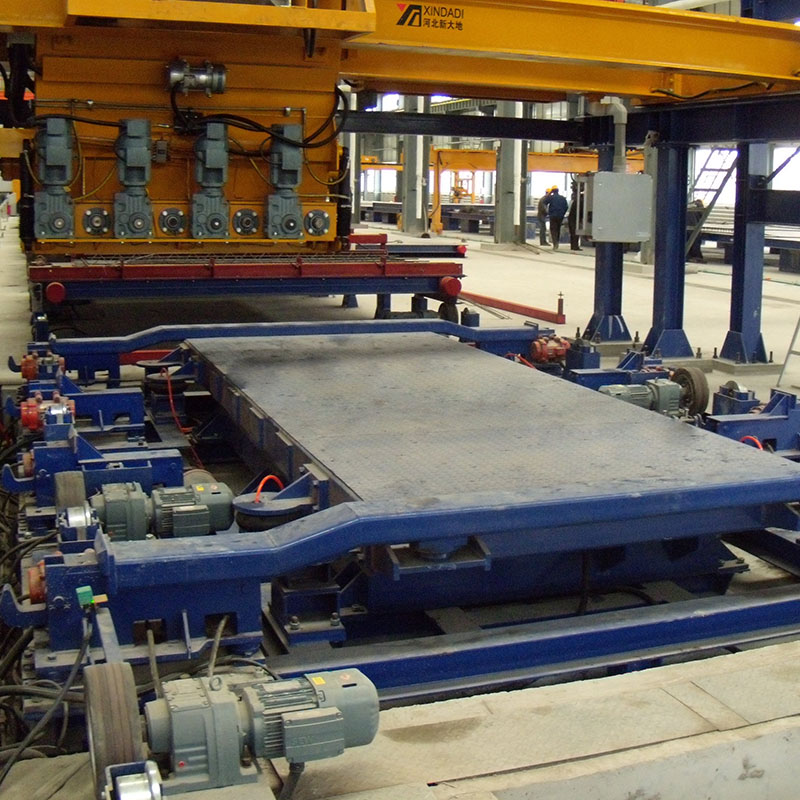

The floor-running principle allows free and easy access between the open panels. Simple demoulding even at low crane hook heights is guaranteed. The chambers can be opened and closed either manually or by motor. The outer panels are moved by means of electric drives. It is operated via radio remote control. In the basic version the moulds are moved mechanically by hand. The vibration-optimised design and the use of special vibrators ensure optimum compaction and the best surface finish. The noise during compaction and wear are reduced.

Technical advantages for the user:

- Possible individual filling of chambers.

- Particular dimensional stability (robust construction with minimal tolerances in flatness).

- The optional built-in heater pipes can be operated with hot water or thermal oil. The consistent temperature distribution ensures the even and energy-saving heating of the precast parts.

- The floor slab and vertical moulds can be made of steel with rubber seal lips to prevent the concrete from leaking out.

- Hydraulic locking with pump control for absolute tightness.

Product detail pictures:

Related Product Guide:

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Quality Inspection for Concrete Bed Flatting Machine With Vibrating - Battery Mould – Xindadi , The product will supply to all over the world, such as: America, Dubai, Bogota, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!