Rapid Delivery for Partition Slabs Production Line - concrete vibrator – Xindadi

Rapid Delivery for Partition Slabs Production Line - concrete vibrator – Xindadi Detail:

Equipment function

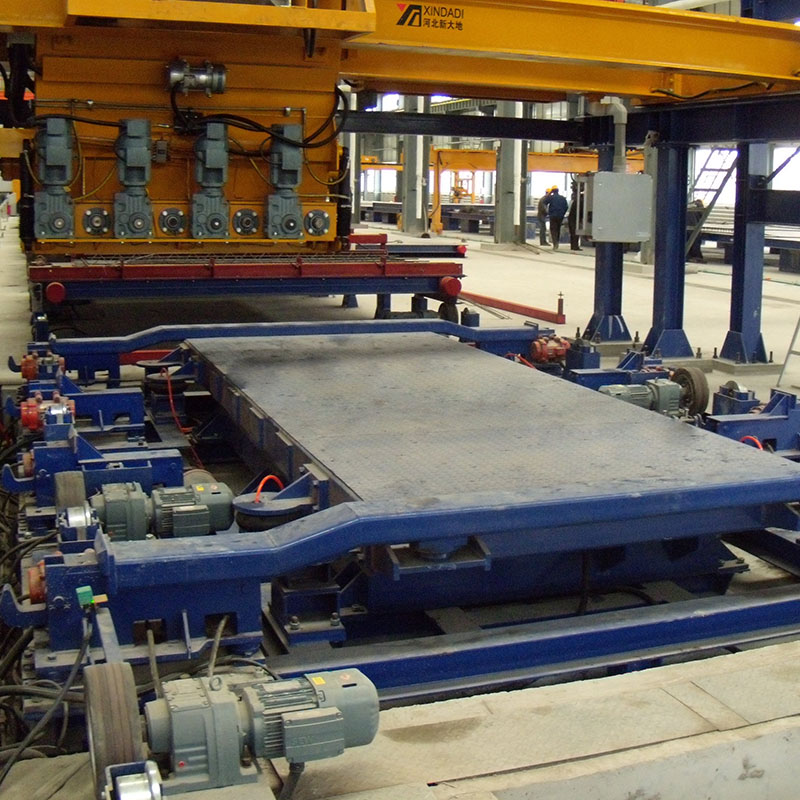

vibration table is used for the prefabricated component production line to vibrate and compact the concrete filled into the pallet by the concrete distributor. The vibrating table is generally arranged under the concrete distributor. The lifting roller, roller conveyor line and vibrating table are closely connected. When the pallet is moved to the vibrating station on the roller conveyor line, the lifting roller in the raised state continues to transport the pallet. After being in place, the lifting roller down to place the pallet on the vibrating table.

Equpment feature

n The hydraulic system can lock the pallet and the vibration table, and the effect of the excitation force transmitted to the pallet is better.

n The vibration frequency and excitation force of the vibration table can be adjusted according to different requirements.

n The vibrating table adopts high frequency vibrating, which has better vibrating effect and less damage to the pallet

n A vibration isolation rubber pad is provided under the vibrating table base to transmit all the excitation force to the pallet.

n Parameters such as frequency, time, and excitation force required by components can be set arbitrarily.

n The control program has a memory mode.

Equipment composation

Standard item

n Lifting roller device

n Lifting drive device

n Single vibration table

n Electrical System

n Hydraulic system

Optional item

o Shaking mechanism

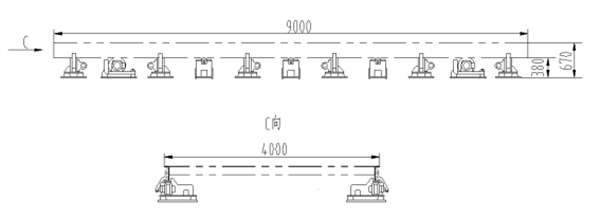

The main technical parameters

Total power of vibration motor: 24kW

Vibration motor excitation force: 96~216kN

Amplitude: 1.0~1.5mm

Vibration frequency: 80~120Hz

Lifting height of lifting roller: 40mm

Drive motor rated power: 2×1.5 kW

Drive device convey speed: 0~0.5 m/s

Equipment weight: ≈4000kg

Product detail pictures:

Related Product Guide:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for Rapid Delivery for Partition Slabs Production Line - concrete vibrator – Xindadi , The product will supply to all over the world, such as: Greece, Jamaica, Bangladesh, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.