Renewable Design for Precast Wall Construction - Balcony Mould – Xindadi

Renewable Design for Precast Wall Construction - Balcony Mould – Xindadi Detail:

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★Moulds Introduction

Our company’s moulds include prefabricated building moulds, municipal road and bridge moulds, wind power tower moulds, high-speed railway moulds, mould tables and prefabricated components supporting tooling and hangers.

Prefabricated building moulds include stair moulds, wall panel moulds, special-shaped moulds, beam-column moulds, laminated plate moulds, double-T plate moulds, and 3D house moulds; municipal road and bridge moulds include small and medium-sized moulds, pipe gallery moulds, prefabricated bridge moulds, subways segment moulds; wind power tower moulds include cone-type tower moulds, segmented tower moulds; high-speed railway moulds include double-block sleeper moulds, prestressed sleeper moulds, trapezoidal sleeper moulds, track plate moulds; The pallet contains circulation line pallet, fixed pallet, pre-stressed pallet, customized pallet; prefabricated components supporting tooling and hangers include spreaders, storage racks and transport racks;

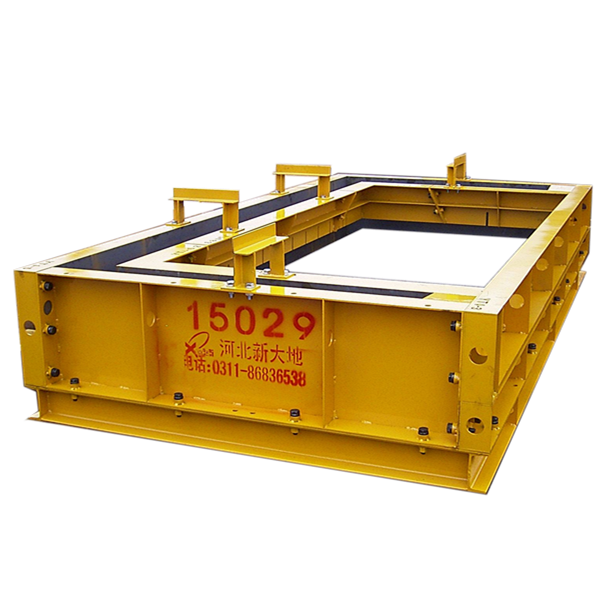

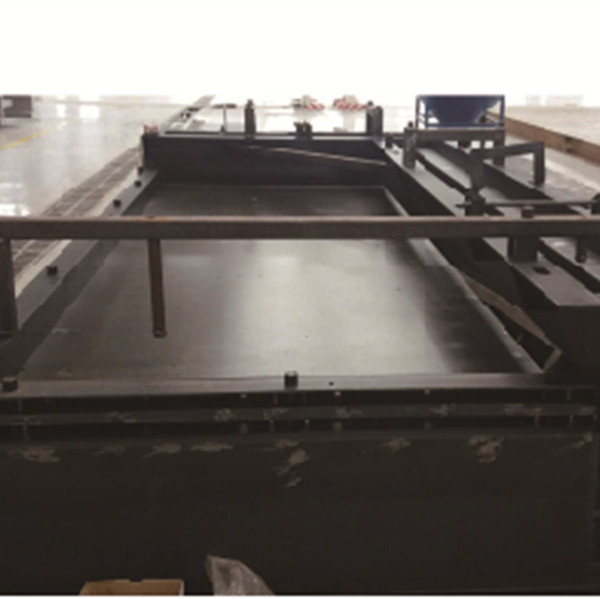

★Product Introduction

Xindadi circulation plants for balcony production offer a high degree of automation. This enables extremely efficient production. The system concept focuses on the optimal use of space with short travel routes and minimal cycle times in order to exploit previously unattainable production capacity potential.

1. Specialised workstations

2.Central material supply and formwork storage

3.Optimised cycle time thanks to workplace organisation

4.Short processing time for uniform elements

5.High output with optimal hardness range

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Renewable Design for Precast Wall Construction - Balcony Mould – Xindadi , The product will supply to all over the world, such as: Victoria, Johor, Mumbai, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.