Short Lead Time for Precast Element Circulation Line - mould tilting machine – Xindadi

Short Lead Time for Precast Element Circulation Line - mould tilting machine – Xindadi Detail:

Equipment function

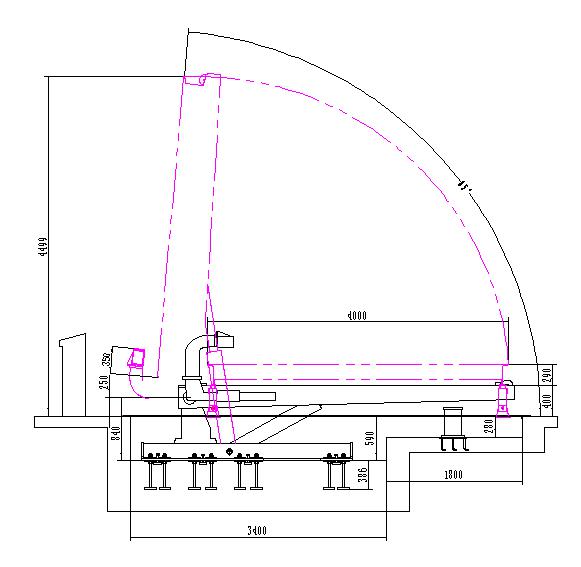

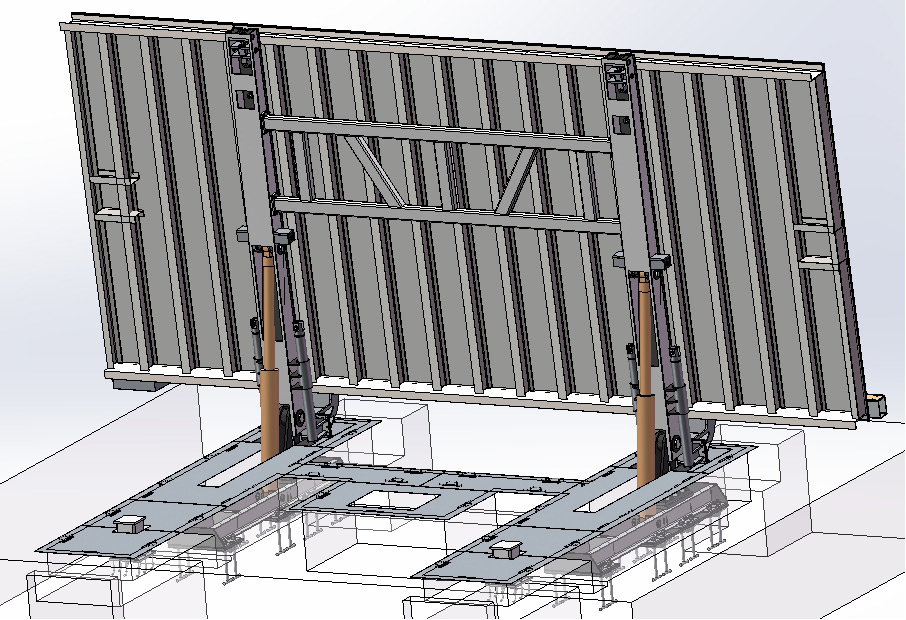

Tilting table is used for turning over PC component pallet with PC component in production line. After the mould removal is completed, the tilting table turns the pallet and PC components to nearly 90° to ensure that the PC components are not damaged during the lifting process.

Equipment feature

The component supporting beam can prevent the component from falling off when turned over, and the top supporting device can realize the component supporting at any position within 400mm of the edge of the pallet.

n The two turning arms realize the synchronous turning of the two turning arms through a high-precision hydraulic system.

n The turning moment of the turning machine is large, which ensures that the beam can rotate smoothly in the predetermined direction when the pallet and the PC component are turned.

n The hydraulic system guarantees the stability of hydraulic reversal and the start and stop at any position within the working range.

n The turning and jacking of the tilting table adopts hydraulic locking device, and the turning and jacking action is safe and reliable.

n The control uses related buttons on the control panel, which is simple and convenient.

Structure and composition

n Tilting support

n Tilting arm

n Jacking device

n Component bearing beam

n Locking device

n Small support

n Hydraulic system

n Electrical system

n Bearing beam support

The main parameters

Tilting load ≤25t

Tilting angle: 0°~85°

Tilting time: up 90s

down 60s

Tilting synchronization: ≤3%

Hydraulic system pressure: 16MPa

Fuel tank capacity: 270L

Motor power: 11KW

Total weight: 5.0t

Power: 380V±20%

Standard accessories and optional accessories (bearing beam support)

Optional item:Inner wall pannel and outside wall pannel process

Distance between large beam and pallet 34mm-114mm.

Standard configuration: It is suitable for the external wall pannel process, and meets the distance between the large beam and the pallet 124mm-204mm.

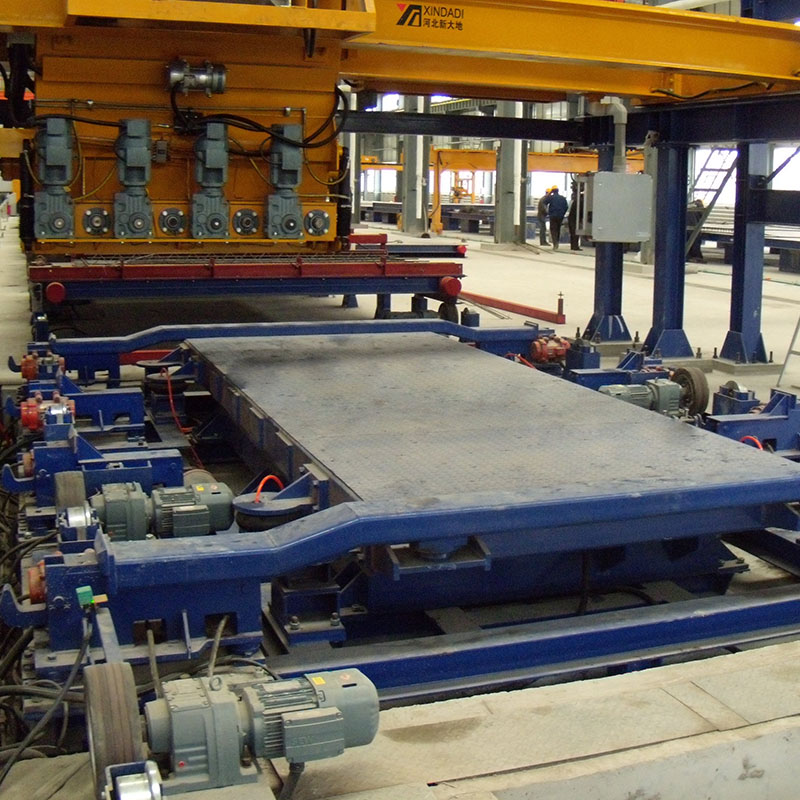

Product detail pictures:

Related Product Guide:

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for Short Lead Time for Precast Element Circulation Line - mould tilting machine – Xindadi , The product will supply to all over the world, such as: luzern, Montreal, Ecuador, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.