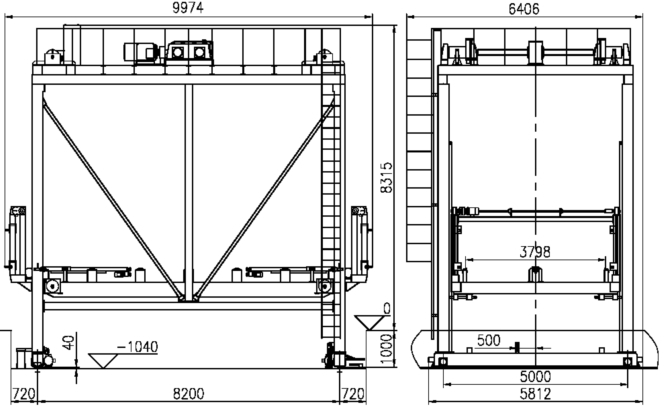

Special Design for Ready Made Concrete Pre-Curing Chamber - Pallet Stacker – Xindadi

Special Design for Ready Made Concrete Pre-Curing Chamber - Pallet Stacker – Xindadi Detail:

The stacker sends the polished or roughened PC components and their pallet from the roller conveyor line to the designated location of the curing chamber;and the cured PC components and their pallet are taken out of the curing and transported to the roller conveyor line.The stacker control system has two control modes, manual and automatic. The automatic mode can set the action cycle arbitrarily,and the site can be unattended.

★Equipment composition

Standard item:

1.Walking system

2.Frame

3.Lifting system

4.Pallet conveyor system

5.Jack/pull pallet mechanism

6.Vertical positioning mechanism

7.Horizontal positioning mechanism

8.Door lift mechanism

9.Control System

10.Hydraulic system

11.Controlling software

12.Guardrail, cage ladder

Optional item:

1.Simulative monitor system

2.Video monitor system

3.Walking track

★Equipment feature

(1) It can automatically identify the pallet and storage position, automatically access the pallet, and automatically open and close the chamber door;

(2) Electrical + mechanical dual positioning system, high positioning accuracy;

(3) The horizontal running and the lifting of the mold table are synchronized to improve the operation efficiency;

(4) Multiple safety measures are set for the lifting system and the taking/feeding mechanism, so that the operation is stable, safe and reliable;

(5) Configure sound and light alarm device;

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★System Introduction

The production system for precast concrete elements has circulation production system,prestressed production system,stationary production system,flexible production system and nomadic production system.

★Molds Introduction

The molds are divided into prefabricated building molds, municipal road and bridge molds, wind power tower molds, high-speed railway molds, mold tables, prefabricated components supporting projects and hangers.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Special Design for Ready Made Concrete Pre-Curing Chamber - Pallet Stacker – Xindadi , The product will supply to all over the world, such as: Boston, Greece, Nicaragua, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.