Well-designed Lattice Girder Vibrating Table - Stationary Production Line – Xindadi

Well-designed Lattice Girder Vibrating Table - Stationary Production Line – Xindadi Detail:

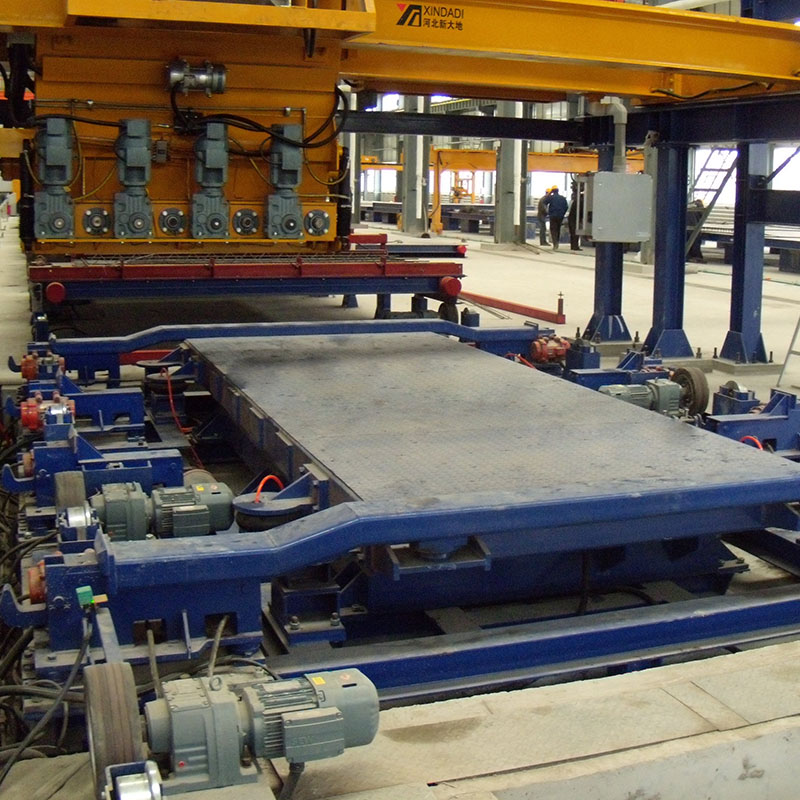

The flexible production concept with its manufacturing cells to be customised is ideal for getting started with the production of precast concrete parts. Stationary production facilities consist of stationary casting beds, stationary moulds or tilting tables. XINDADI manufactures a whole range of proven technical variants for the production of diverse precast concrete parts.

The flexible production concept with customizable production islands.

Whoever needs to produce a wide product range of precast concrete parts with different shuttering concepts can go the route of stationary production based on the principle of cell production. The individual types of formwork (stationary casting bed, tilting table, vibrating table, battery mould, mould for columns and beams, staircase formwork) are organisationally grouped together and the material flow of fresh concrete and reinforcement bars is planned accordingly. Although stationary production facilities have a lower output per hour than circulation systems, they allow more flexible production programmes.

Single-item production of precast concrete parts is consolidated in a uniform and efficient production concept. XINDADI stationary production comprises the entire concrete supply, from the mixing plant by means of a bucket conveyor to the individual manufacturing cells. The consistent and continuous design of the production process, including the planning of material buffers, is the alpha and omega of this concept: concrete dosage > concrete compaction > formwork handling > transport of the precast concrete parts by means of run-off technology and special stacking frames > loading directly onto the truck.

Product detail pictures:

Related Product Guide:

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Well-designed Lattice Girder Vibrating Table - Stationary Production Line – Xindadi , The product will supply to all over the world, such as: Moscow, Lisbon, Romania, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.